-

PHONE

+39 0522 964949 -

PRICE LIST

Ask for the price list

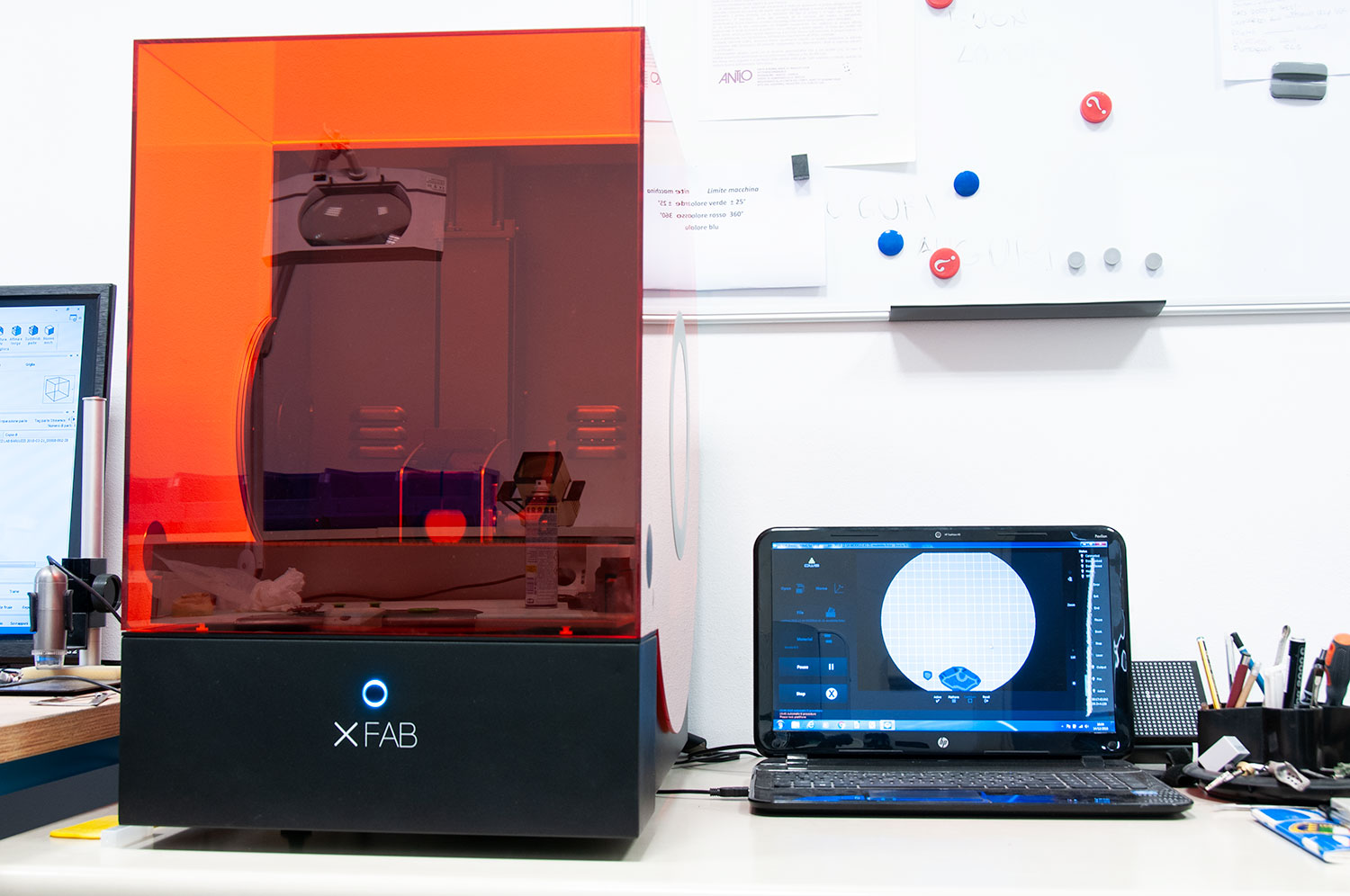

3D printing is undergoing exponential growth in the dental industry, thanks to the development of tools designed specifically for this sector and the availability of a wide range of materials dedicated to various applications.

The talent of the dental technician is certainly not excluded from this process, rather it comes into play on the basis of the certainty of the production conditions: analogue uncertainty is transformed into digital safety and technicians, who are now spared the manual modeling phase, can concentrate on the growth of their business.

Una delle lavorazioni che può trarre maggiore vantaggio dall’innovativo processo di stampa 3D è la fabbricazione di modelli protesici, tradizionalmente realizzati in gesso e che, grazie alle moderne tecnologie additive, è possibile fabbricare sia in resina che in PA grigia biocompatibile.

La svolta digitale diventa una scelta quasi obbligata per gli odontotecnici che possono affidarsi ad un partner specializzato per la produzione di elementi che offre all’odontotecnico il beneficio di affrontare con maggiore serenità l’innovazione prospettata dalle tecnologie digitali e garantisce al proprio cliente un risultato innovativo e performante in tempi e costi più limitati.

Una delle lavorazioni che può trarre maggiore vantaggio dall’innovativo processo di stampa 3D è la fabbricazione di modelli protesici, tradizionalmente realizzati in gesso e che, grazie alle moderne tecnologie additive, è possibile fabbricare in resina.

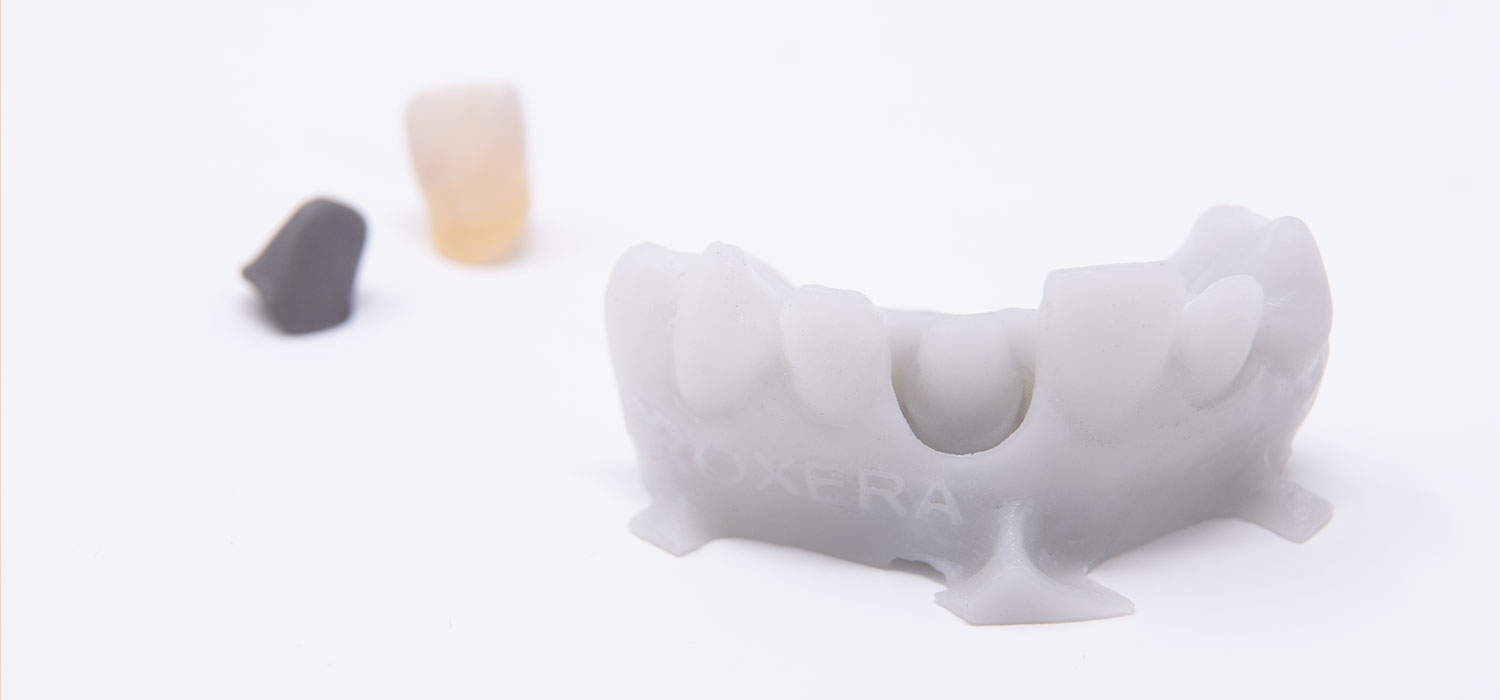

One of the processes that can benefit most from the innovative 3D printing process is the manufacture of prosthetic models, which were traditionally made of plaster but that, using modern additive technologies, can now be manufactured using resin.

Digital technology has become an almost mandatory choice for dental technicians, who can rely on a specialized partner for the production of elements that boast the benefit of adapting to the innovation envisaged by digital technologies with greater ease and is able to guarantee customers an innovative and high-performance result with shorter turnaround times and at lower costs.

The surgical guide is an instrument to help the surgical practice realized with the purpose of containing the elements necessary for the correct positioning of the definitive dental implant.

It consists of a guide, usually made of resin or polymeric material, which is placed in the oral cavity of the patient, allowing the surgeon to insert the implant screw in the optimal position, reducing the possibility of making positioning errors.

Proxera offers two different types of 3D printed surgical guides.

The first, most commonly requested, is made of resin, typically light blue in color, using large industrial PolyJet equipment. The combination of material and technology allows for excellent surface definition.

The second involves manufacturing the surgical guide using a biocompatible light grey PA powder. This powder is processed in HP's Multijet Fusion equipment which, while maintaining good surface definition, reduces fabrication time and therefore the final cost to the dental technician.

Both solutions allow a perfect adherence to the project specifications and allow the realization of a surgical guide perfectly adapted to the use by the clinic.o

In dental technology, specimens are traditionally made from metallic materials such as aluminum, the rigidity of which is exploited to ensure that the piece fits and is functional.

The classical machining involved in a structure such as this is such that there is significant dispersion affecting several aspects of machining for a part that will only be used for a few minutes.

The specimen is burdened by the costs of the aluminum disc, a large part of which will be lost due to the noteworthy waste of material, and the persistent use of a milling machine implies maintenance costs. The working times required by the system are once again excessive if compared to the function that the product in question has to cover.

3D printing comes to the aid of the dental technician, offering him resin specimens that have the advantage of being cheaper and faster to make. The material used in the printing process provides the same rigidity as aluminum, so that when the patient is tested, it fits perfectly without deformation.

Relying on 3D printing when making a test specimen is a wise move, especially when considering the possibility of unforeseen complications. In fact, if at the time of the mouth test, the specimen doesn't work because of an incorrect impression or misaligned stumps, the investment made up to that point would be wasted.

© Copyright 2021. All Rights Reserved. Proxera S.r.l. - Via Marchesi, 1 - 42022 Boretto (RE)

C.F. / P.IVA / Reg. Imp. RE 02741880351- R.E.A. 309389- Cap. Soc. € 30.000,00 i.v.a.

Information on the processing of personal data | General terms of sales | Cookies Policy